The first frost hits your vegetable garden, and suddenly you’re faced with a familiar dilemma: what to do with the abundance of produce that seemed like such a blessing just weeks ago. For Australian households pursuing self-sufficiency, this seasonal transition marks one of the most critical periods of the year. The difference between a well-fed winter and expensive trips to the supermarket often comes down to how effectively you can preserve your autumn harvest and ultimately, what your winter food storage & preservation plan looks like.

Food preservation isn’t just about extending shelf life, it’s about maintaining nutritional value, reducing waste, and building genuine food security for your household. When grocery prices spike during winter months, as they inevitably do, your preserved foods become both a financial cushion and a source of pride. You’re eating food you grew, harvested, and preserved yourself, maintaining a connection to your land and seasons that most Australians have lost.

This comprehensive guide covers seven proven preservation methods that work specifically well in Australian conditions. Each technique offers unique advantages, and when combined strategically, they create a robust food storage system that can carry your household through the leanest months with confidence and abundance.

Why Food Preservation Matters More Than Ever in Australia

Australia’s food security landscape has shifted dramatically in recent years. Supply chain disruptions, extreme weather events, and rising transportation costs have all contributed to increased grocery volatility. For rural Australians, these challenges are compounded by limited access to fresh produce during winter months, particularly in remote areas where freight costs add significant premiums to basic foods.

The economic case for food preservation is compelling. A typical Australian family spends between $150-300 weekly on groceries, with fresh produce accounting for roughly 30% of that budget. During winter, when local growing slows and imported produce dominates supermarket shelves, these costs can increase by 40-60%. By preserving peak season abundance, you’re essentially buying insurance against these price fluctuations while ensuring your family maintains access to nutrient-dense, chemical-free food.

Beyond economics, food preservation provides psychological benefits that shouldn’t be underestimated. There’s profound satisfaction in opening a jar of tomatoes you canned in February to make pasta sauce in July. It represents control over your food supply, reduced dependence on complex supply chains, and a tangible connection to the natural cycles that govern food production.

Key benefits include: • 40-60% reduction in winter grocery costs • Improved nutrition through home-grown, preservative-free foods • Enhanced food security during supply disruptions • Reduced household food waste • Deeper connection to seasonal eating patterns

1. Dehydrating: Harnessing Australia’s Natural Advantages

Australia’s generally dry climate provides natural advantages for dehydration, making this one of the most accessible preservation methods for beginners. Dehydration works by removing moisture that bacteria, yeasts, and molds need to survive, while concentrating flavors and many nutrients. The process transforms perishable foods into shelf-stable products that can last months or even years when properly stored.

The science behind dehydration is elegantly simple. Most spoilage organisms require a water activity level above 0.60 to survive, while properly dehydrated foods typically achieve water activity levels between 0.10-0.60. This dramatic reduction in available moisture creates an environment where harmful microorganisms simply cannot multiply, effectively stopping the spoilage process.

Modern electric dehydrators have revolutionized home food drying, providing consistent temperatures and airflow that produce superior results compared to traditional sun-drying methods. However, Australia’s intense sun and low humidity in many regions still make solar dehydration viable for certain foods, particularly in inland areas during dry seasons.

The versatility of dehydration makes it particularly valuable for Australian households. Summer’s abundant stone fruits can be transformed into concentrated flavor bombs perfect for winter baking. Surplus zucchini, that nemesis of every vegetable gardener, becomes valuable chips or powder for thickening soups. Herbs grown in abundance during warm months retain their potency when properly dried, providing flavorful alternatives to expensive store-bought seasonings.

Equipment considerations for Australian conditions:

- Sunbeam Food Lab Pro DT6000: Budget-friendly option suitable for occasional use

- Excalibur 4926T: Mid-range choice with precise temperature control and ample capacity

- Harvest Right Freeze Dryer: Premium investment for serious preservation enthusiasts

Storage becomes critical in Australia’s variable climate. Humidity can vary dramatically between seasons and regions, making proper containers essential. Glass jars with tight-fitting lids work well for herbs and small batches, while vacuum-sealed bags excel for larger quantities. The key is removing as much air as possible and storing in cool, dark locations where temperature remains relatively stable.

2. Water Bath Canning: Mastering High-Acid Food Safety

Water bath canning represents one of the safest and most reliable preservation methods for high-acid foods, making it ideal for Australia’s abundant citrus harvests and the pickled vegetables that feature prominently in sustainable eating. The process relies on the natural acidity in foods (pH 4.6 or lower) combined with heat processing to create shelf-stable products that can last for years.

The chemistry of water bath canning centers on pH levels and heat penetration. High-acid foods create an environment where Clostridium botulinum spores cannot germinate, even if they survive the heating process. When combined with the 100°C temperature achieved in boiling water, this creates a preservation method that has proven safe and effective for over a century.

Understanding pH is crucial for safe water bath canning. Tomatoes sit right at the borderline, which is why most recipes call for added acid in the form of lemon juice or citric acid. Stone fruits, citrus, and most pickled vegetables fall comfortably within safe pH ranges, while vegetables like green beans and corn require pressure canning due to their low acid content.

The Australian climate presents unique opportunities for water bath canning enthusiasts. Our extended citrus season means fresh fruit for marmalades and preserves is available for months rather than weeks. Stone fruit abundance in summer creates opportunities for jams, chutneys, and whole fruit preserves that capture peak flavors for winter enjoyment.

Jar selection becomes particularly important in Australia’s temperature extremes. Quality canning jars designed for thermal shock perform better than repurposed containers, which can crack or fail to seal properly when exposed to temperature variations. The investment in proper equipment pays dividends in both safety and success rates.

Processing times may need adjustment for altitude, though most Australian populated areas sit close to sea level. However, the intense heat of Australian summers means careful attention to cooling procedures becomes even more critical to prevent thermal shock and ensure proper sealing.

3. Pressure Canning: Unlocking Low-Acid Food Preservation

Pressure canning opens up preservation possibilities that water bath canning simply cannot safely achieve. By reaching temperatures of 116°C under pressure, this method destroys botulism spores that can survive in low-acid environments, making it possible to safely preserve vegetables, meats, and complete meals for long-term storage.

The physics of pressure canning work by increasing atmospheric pressure inside the canner, which raises the boiling point of water above 100°C. This higher temperature is essential for destroying Clostridium botulinum spores, which can survive in low-acid environments and produce deadly toxins if given the opportunity to germinate. The precision required makes pressure canning initially intimidating, but the safety protocols are straightforward when followed consistently.

For Australian households, pressure canning represents freedom from refrigerator dependence. Rural properties with unreliable power or off-grid homes benefit enormously from shelf-stable proteins and vegetables that require no electricity for storage. During bushfire seasons or extreme weather events that can disrupt power for days, pressure-canned foods provide security and nutrition when fresh options aren’t available.

The range of foods suitable for pressure canning encompasses most of what Australian gardeners grow in abundance. Green beans, corn, carrots, and potatoes all preserve beautifully under pressure. Meat preservation becomes particularly valuable during hunting seasons or when processing home-raised livestock, allowing you to preserve large quantities safely without overwhelming freezer capacity.

Modern pressure canners have evolved significantly from the intimidating models our grandparents might remember. Contemporary designs include multiple safety features, pressure release systems, and accurate gauges that take much of the guesswork out of the process. The All American models, while expensive, represent the gold standard for safety and durability, often lasting decades with proper maintenance.

Critical safety elements:

- Annual pressure gauge testing ensures accurate processing

- Using only tested recipes from reputable sources

- Proper venting procedures before pressurizing

- Natural cooling without forced pressure release

Processing times must account for Australian altitude variations, though adjustments are minimal for most populated areas. The bigger consideration is seasonal temperature extremes, which can affect cooling times and require modifications to processing schedules during peak summer heat.

4. Fermentation: Ancient Wisdom for Modern Kitchens

Fermentation represents humanity’s oldest preservation method, and its recent resurgence reflects both culinary interest and growing understanding of gut health benefits. For Australian households, fermentation offers unique advantages: it requires minimal equipment, works well in warm climates with proper management, and actually improves nutritional content while preserving food.

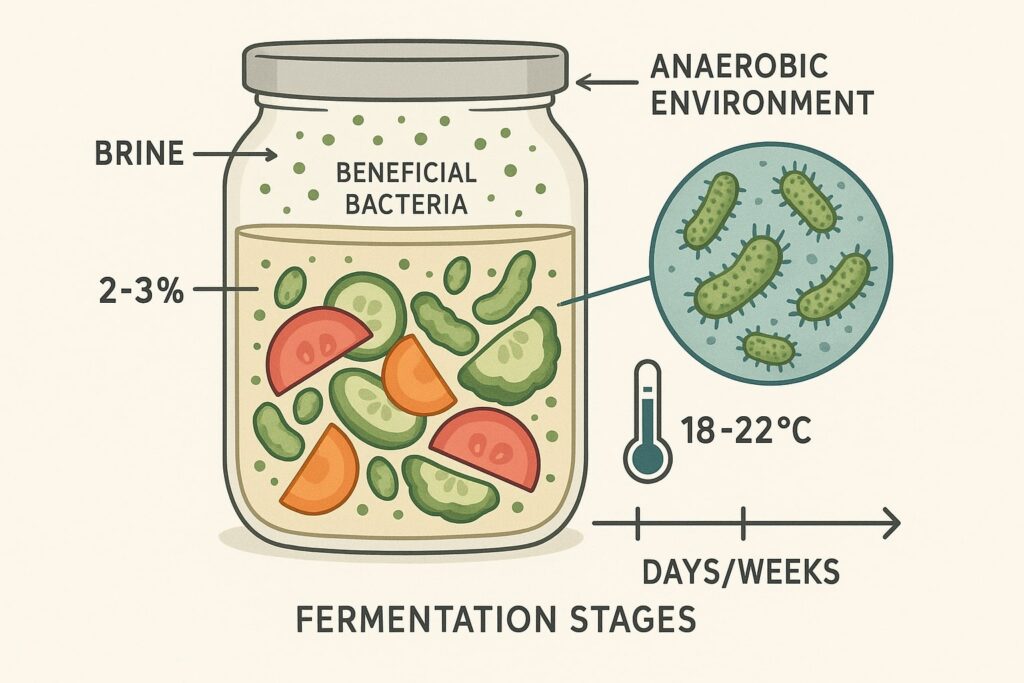

The biological process behind fermentation harnesses beneficial bacteria, primarily lactobacilli, to create acidic environments that preserve food while developing complex flavors. These beneficial microorganisms consume sugars in vegetables, producing lactic acid that drops pH levels below 4.0, creating conditions where harmful bacteria cannot survive. The process essentially turns your kitchen into a controlled ecosystem where good bacteria outcompete potentially dangerous ones.

Australia’s warm climate accelerates fermentation, which can be both advantage and challenge. Vegetables that might take weeks to ferment in cool European cellars can be ready in days during Australian summers. This rapid fermentation allows for quicker turnover and fresher flavors, but requires more attention to prevent over-fermentation or development of off-flavors.

Traditional European fermentation techniques adapt beautifully to Australian produce. Cabbage transforms into sauerkraut or kimchi using locally grown vegetables. Root vegetables like carrots, beetroot, and radishes develop tangy complexity through lacto-fermentation. Even fruits can be fermented, with grapes, apples, and stone fruits creating alcohol-free fermented beverages rich in probiotics.

The salt ratios become critical in Australia’s warm conditions. Most vegetable ferments require 2-3% salt by weight, but higher temperatures may call for slightly increased salt content to slow fermentation and prevent over-development. Quality salt without additives is essential-iodized table salt can inhibit fermentation, while mineral-rich sea salt or rock salt provides trace elements that support bacterial health.

Temperature control challenges in Australian homes often require creative solutions. Fermentation crocks work well, but simple mason jar setups can be equally effective with proper attention. During extreme heat periods, fermentation vessels may need climate-controlled environments or careful timing to avoid temperature spikes that can kill beneficial bacteria or encourage unwanted microorganisms.

The nutritional benefits of fermentation extend beyond preservation. The bacterial action increases bioavailability of many nutrients while creating new vitamins, particularly B vitamins and vitamin K2. For households focused on optimal nutrition from home-grown foods, fermentation represents a way to enhance rather than merely preserve nutritional content.

5. Root Cellaring: Natural Refrigeration for Australian Conditions

Root cellaring capitalizes on stable underground temperatures to provide natural refrigeration without electricity, making it particularly valuable for Australian properties where power costs are high or reliability is questionable. While traditional root cellars work best in consistently cool climates, Australian households can adapt these principles using modern materials and techniques to create effective cold storage systems.

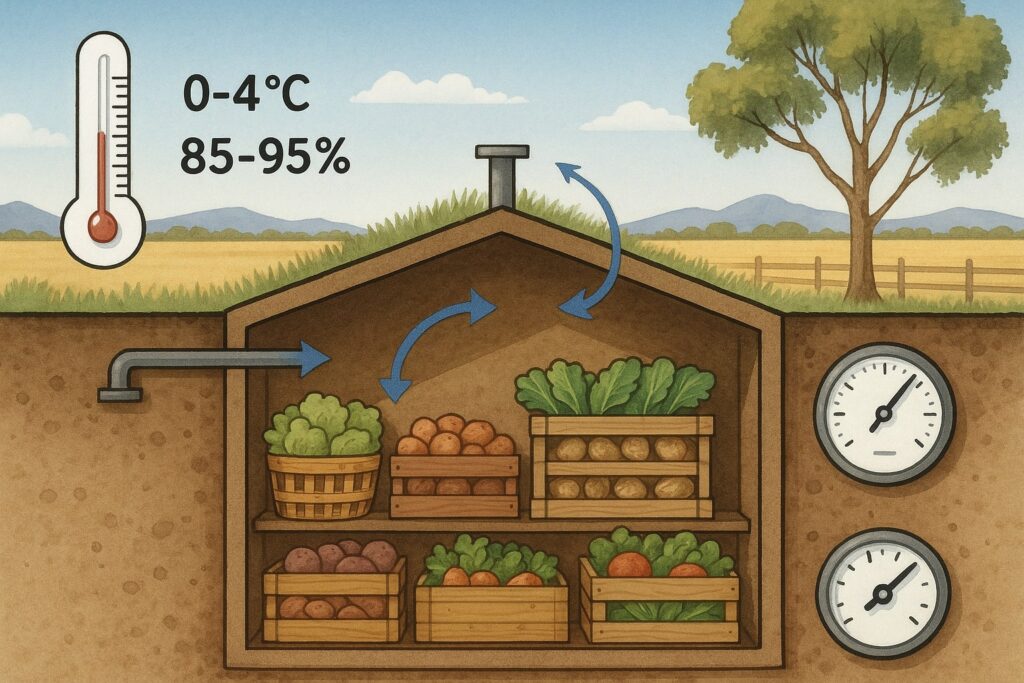

The science behind root cellaring relies on three key factors: temperature, humidity, and air circulation. Most storage vegetables prefer temperatures between 0-4°C with high humidity (85-95%) and good air movement to prevent condensation and mold development. These conditions slow cellular respiration and transpiration while preventing dehydration, significantly extending storage life for many vegetables.

Australian climate zones present varying opportunities for root cellaring. Southern regions with genuine winter cold can support traditional underground systems, while northern areas may require more creative approaches. Even in subtropical zones, partially underground storage areas can maintain temperatures several degrees below ambient, extending storage life considerably compared to room temperature storage.

Construction approaches vary based on local conditions and budget. Converted shipping containers, either partially buried or well-insulated above ground, create excellent storage environments when properly ventilated. Underground concrete installations work well in areas with stable soil conditions, while earth-bermed sheds provide compromise solutions that are less expensive but still effective.

Ventilation becomes critical in Australian conditions where temperature swings can be dramatic. Passive ventilation systems using convection can maintain air movement without electricity, while simple exhaust fans on timers provide more precise control. The goal is preventing stagnant air that encourages mold while avoiding drafts that accelerate dehydration.

Ideal vegetables for Australian root cellaring:

- Potatoes: Store 3-6 months in proper conditions

- Carrots: Last 4-8 months when properly prepared

- Beetroot: Excellent keeper, 6+ months possible

- Apples: Many varieties store 3-6 months

- Onions: Cure properly for 6-12 month storage

Preparation methods significantly impact storage success. Potatoes need curing in warm, humid conditions before cool storage. Root vegetables benefit from removing tops while leaving root tails intact. Apples require careful handling to prevent bruising, with damaged fruit removed immediately to prevent spread of decay.

Monitoring systems help maintain optimal conditions year-round. Digital thermometers with external sensors allow checking temperatures without opening storage areas frequently. Humidity gauges help identify when ventilation adjustments are needed. Simple rotation schedules ensure older produce gets used first while monitoring for signs of deterioration.

6. Smoking: Combining Preservation with Flavor Enhancement

Smoking represents one of the most complex preservation methods, combining dehydration, chemical preservation from smoke compounds, and heat treatment to create uniquely flavored foods with extended shelf life. For Australian households, smoking offers particular advantages during hunting seasons, fishing expeditions, or when processing home-raised livestock in larger quantities.

The preservation mechanisms in smoking are multifaceted. Heat dehydrates food while smoke deposits antimicrobial compounds including formaldehyde, phenols, and organic acids that inhibit bacterial growth. Cold smoking (15-25°C) focuses primarily on flavor development and surface preservation, requiring additional preservation methods for long-term storage. Hot smoking (80-90°C) combines cooking with preservation, creating ready-to-eat products with moderate shelf life.

Wood selection becomes particularly important in Australia, where many native species can be toxic or impart unpleasant flavors. Fruit woods like apple and cherry provide mild, sweet smoke that works well with fish and poultry. Hardwoods such as oak, hickory, and ironbark create stronger flavors suitable for red meats. Avoiding resinous woods like pine and most eucalyptus species is critical, as these can produce bitter or potentially harmful compounds.

Australian regulations around smoking vary by state, with some areas restricting outdoor smoking during fire danger periods. Electric smokers provide more control and can often be used when wood-fired equipment is prohibited. Understanding local regulations and fire safety requirements is essential before investing in smoking equipment.

The climate considerations in Australia make smoking both easier and more challenging than in traditional smoking regions. Low humidity accelerates moisture removal, reducing smoking times but requiring careful monitoring to prevent over-drying. High temperatures can make cold smoking difficult during summer months, shifting optimal smoking seasons to cooler periods.

Food safety in smoking requires particular attention to temperature control and timing. Internal temperatures must reach safe levels for the specific protein being smoked, with digital thermometers providing the accuracy needed for consistent results. Curing salts become important for cold-smoked products, providing additional protection against botulism in low-acid, low-oxygen environments.

Equipment considerations:

- Electric smokers: Precise temperature control, suitable for fire-restricted periods

- Offset smokers: Traditional approach, requires more skill but provides excellent results

- Cabinet smokers: Compact design suitable for smaller properties

- DIY options: Converted refrigerators or barrels can work well with proper modification

The learning curve for smoking is steeper than other preservation methods, but the results justify the effort. Properly smoked salmon can last weeks under refrigeration, while hot-smoked vegetables provide unique flavors for winter meals. The social aspect of smoking also creates opportunities for community skill-sharing and bulk processing sessions.

7. Freeze Drying: Premium Preservation Technology

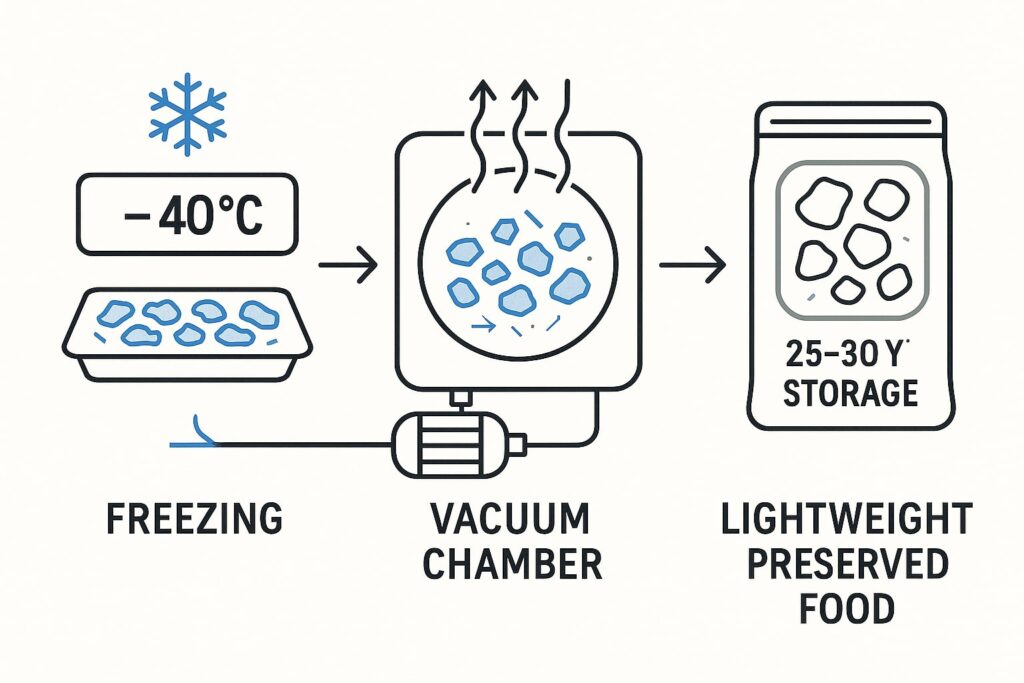

Freeze drying represents the pinnacle of home food preservation technology, removing 98% of moisture while maintaining original food structure and nutritional content. While the initial investment is substantial, freeze drying offers unmatched shelf life and food quality, making it increasingly popular among serious preservation enthusiasts and emergency preparedness advocates.

The freeze drying process works through sublimation-frozen food is placed in a vacuum chamber where ice crystals transform directly from solid to vapor without passing through liquid phase. This gentle process preserves cellular structure better than any other preservation method, maintaining textures, flavors, and nutritional content that approach fresh food quality when rehydrated.

For Australian households, freeze drying offers unique advantages in our climate extremes. Unlike dehydration, which can be affected by humidity and requires careful monitoring, freeze drying produces consistently excellent results regardless of ambient conditions. The long shelf life (25-30 years when properly stored) makes it ideal for emergency preparedness, while the light weight of freeze-dried foods appeals to camping and travel enthusiasts.

The economics of freeze drying require careful consideration. Quality home units range from $3,000-$8,000, with operating costs of $1-3 per load depending on electricity rates and batch sizes. However, the ability to preserve complete meals, expensive ingredients, and seasonal produce at peak quality can justify the investment for households serious about food preservation.

Batch planning becomes important to maximize efficiency and return on investment. Complete meals freeze dry well, allowing busy families to preserve home-cooked food for later consumption. Seasonal produce like berries, which are expensive when out of season, provide excellent return when preserved at peak quality and abundance. Herbs and specialty ingredients maintain potency that dried herbs cannot match.

Optimal foods for freeze drying:

- Complete cooked meals: Soups, stews, casseroles retain original flavors and textures

- Seasonal fruits: Berries, stone fruits maintain fresh-like quality

- Herbs: Superior potency retention compared to air drying

- Dairy products: Cheese, yogurt preserve well with proper technique

- Leftovers: Transform excess cooking into convenient future meals

Storage requirements for freeze-dried foods are minimal but specific. Oxygen absorbers and mylar bags inside rigid containers provide optimal long-term storage. The low moisture content makes freeze-dried foods relatively stable, but protecting from moisture reabsorption remains critical for maintaining quality and shelf life.

The rehydration process is typically simple-most foods reconstitute with hot or cold water in minutes. The convenience factor often surprises first-time users, as freeze-dried foods can go from storage to table faster than many fresh food preparations.

Strategic Seasonal Planning for Maximum Efficiency

Successful food preservation requires thinking systematically about seasonal abundance and storage goals. Rather than responding reactively to surplus produce, strategic planning maximizes both preservation efficiency and food quality while minimizing time investment during busy periods.

Autumn represents the peak preservation season for most Australian households. This is when gardens reach maximum productivity while storage vegetables mature for harvest. Planning preservation activities around these natural cycles ensures you’re working with optimal ingredients while spreading workload across manageable timeframes.

Autumn preservation priorities: Spring and summer preparation sets the foundation for autumn’s intensive preservation period. This includes ensuring equipment is functional, storage containers are clean and ready, and preservation supplies are stocked. Growing specifically for preservation requires different varieties and timing than growing for fresh consumption.

Summer preservation focuses primarily on heat-loving crops and fruit harvests. Stone fruits, tomatoes, and herbs reach peak quality during hot months, making this the optimal time for water bath canning, dehydrating, and herb preservation. The long daylight hours and intense heat create ideal conditions for solar dehydration and quick fermentation.

Winter preservation activities shift toward using preserved foods effectively while maintaining quality through proper rotation and storage management. This season also offers opportunities for cold smoking in suitable climates and planning for the following year’s preservation activities.

Equipment maintenance schedules:

- Spring: Test pressure canner gauges, inspect seals and gaskets

- Summer: Clean and calibrate dehydrators, check temperature accuracy

- Autumn: Organize storage containers, update inventory systems

- Winter: Service equipment, order supplies for next season

The integration of multiple preservation methods creates resilience and variety in food storage. Rather than relying heavily on single methods, successful preservation incorporates techniques that complement each other and accommodate different types of produce.

Quality Control and Safety Protocols

Food safety in home preservation requires understanding both the science behind each method and the specific failure points that can compromise safety or quality. While home preservation has an excellent safety record when proper procedures are followed, the consequences of mistakes can be serious enough to warrant careful attention to protocols.

Temperature monitoring provides the foundation for safe preservation across all methods. Digital thermometers with external probes offer accuracy and convenience for monitoring canning temperatures, while infrared thermometers help verify smoking and dehydrating temperatures. Investing in quality monitoring equipment prevents guesswork and provides confidence in results.

pH testing becomes important for borderline foods and fermentation monitoring. Digital pH meters provide accuracy, while pH strips offer convenience for routine checking. Understanding how pH affects safety helps make informed decisions about recipe modifications and processing requirements.

Warning signs requiring immediate attention:

- Bulging lids on canned goods indicate possible botulism contamination

- Off odors from any preserved food suggest spoilage

- Mold growth (except intentional cheese molds) requires discarding affected food

- Texture changes like sliminess or excessive softness indicate deterioration

Documentation and record-keeping support both safety and quality improvement. Recording processing times, temperatures, and results helps identify successful techniques while flagging potential problems. Date labeling ensures proper rotation, while detailed notes support troubleshooting when results don’t meet expectations.

Testing and adjusting techniques based on results and local conditions improves both safety and quality over time. Starting with small batches allows experimentation without major losses, while keeping detailed records supports systematic improvement.

Economic Analysis: Investment Returns and Cost Savings

The financial case for food preservation extends beyond simple grocery savings to include reduced waste, improved nutrition, and enhanced food security. Understanding these economic benefits helps justify initial equipment investments and guides decision-making about which preservation methods provide the best returns for specific households.

Initial setup costs vary dramatically based on chosen methods and equipment quality. A basic preservation setup including water bath canning supplies, dehydrator, and fermentation containers can be assembled for $500-$1,000. Adding pressure canning capability increases investment to $1,500-$2,000, while freeze drying represents a premium investment of $5,000-$10,000 including setup and initial supplies.

Annual savings potential for typical Australian households:

- Grocery bill reduction: $2,000-$5,000 annually for families of 4

- Reduced food waste: $500-$1,200 in prevented losses

- Bulk purchasing opportunities: 20-30% additional savings

- Emergency preparedness value: Difficult to quantify but potentially substantial

The payback period for preservation equipment typically ranges from 1-3 years depending on household size, current food costs, and preservation intensity. Rural households often see faster payback due to higher fresh food costs and greater preservation opportunities, while urban households may take longer but still achieve significant long-term savings.

Beyond direct financial returns, food preservation provides intangible benefits that are difficult to quantify but contribute to overall household value. The security of knowing you can feed your family well regardless of supply disruptions or price spikes provides peace of mind worth considerable premium to many households.

Factors affecting economic returns:

- Household size and food consumption patterns

- Local grocery costs and seasonal price variations

- Garden productivity and surplus management

- Equipment utilization rates and efficiency

- Energy costs for processing and storage

Troubleshooting Common Preservation Problems

Even experienced food preservers encounter occasional failures, and understanding common problems helps prevent both safety issues and discouragement. Most preservation problems stem from procedural errors rather than equipment failures, making knowledge and attention to detail the primary prevention strategies.

Canning failures typically involve seal problems, processing errors, or contamination issues. Failed seals often result from overfilling jars, improper lid preparation, or thermal shock from temperature extremes. Reprocessing is sometimes possible if caught quickly, but often the safest approach involves refrigerating and consuming promptly or discarding if safety is questionable.

Common dehydrating problems and solutions:

- Uneven drying: Improve air circulation, rotate trays regularly

- Case hardening: Reduce initial temperature, increase gradually

- Storage problems: Ensure complete drying, use moisture absorbers

- Off flavors: Check for contamination sources, improve ventilation

Fermentation troubles frequently involve balance issues between salt, temperature, and timing. Too much salt slows fermentation and creates overly salty products, while too little salt allows harmful bacteria to compete with beneficial ones. Temperature extremes kill beneficial bacteria or accelerate fermentation beyond optimal flavor development.

Root cellaring problems typically relate to temperature, humidity, or air circulation imbalances. Monitoring systems help identify problems before they become serious, while good preparation and rotation practices prevent most storage failures.

The key to successful troubleshooting is maintaining detailed records of procedures, conditions, and results. This documentation helps identify patterns and successful approaches while flagging techniques that need adjustment for local conditions.

Building Community Around Food Preservation

Food preservation creates natural opportunities for community building and skill sharing that enhance both learning and social connections. Traditional preservation knowledge often exists within local communities, and tapping into these resources can accelerate learning while building valuable relationships.

Local preservation groups, often organized through permaculture societies, landcare groups, or community gardens, provide forums for sharing knowledge, equipment, and bulk purchasing opportunities. These groups often organize workshops, equipment sharing programs, and group processing sessions that make large preservation projects more manageable and enjoyable.

Community preservation activities:

- Group canning sessions for large harvests

- Equipment sharing programs for expensive items

- Skill workshops for new preservation methods

- Bulk purchasing cooperatives for supplies

- Recipe sharing and testing groups

The teaching aspect of preservation skills creates opportunities to contribute to community knowledge while reinforcing your own understanding. Experienced preservers often find that explaining techniques to others helps identify areas for improvement in their own practices.

Social media groups and online forums extend community connections beyond geographic limitations, providing access to preservation enthusiasts across Australia and internationally. These platforms offer troubleshooting help, recipe sharing, and motivation during challenging preservation seasons.

Your Path Forward: Starting Your Preservation Journey

Beginning food preservation can feel overwhelming given the range of methods and equipment options available. The key to success lies in starting small, mastering basic techniques, and gradually expanding both skills and equipment as confidence and experience grow.

Most preservation educators recommend starting with one or two methods that appeal to your interests and match your available time and budget. Water bath canning and dehydrating represent excellent entry points-both are relatively safe, require modest equipment investments, and provide quick satisfaction through usable results.

Recommended progression for new preservers:

- Year 1: Master water bath canning and dehydrating basics

- Year 2: Add fermentation and expand canning repertoire

- Year 3: Consider pressure canning or specialty methods

- Ongoing: Refine techniques, experiment with new foods, teach others

Setting realistic goals prevents discouragement while building sustainable preservation habits. Planning to preserve 25% of your winter vegetable needs is more achievable than attempting complete self-sufficiency in the first year. Success breeds confidence, which encourages continued learning and expansion.

The investment in preservation skills and equipment represents more than simple food storage – it’s an investment in household resilience, food security, and connection to natural cycles that sustain human life. Each preserved jar, dried fruit batch, or fermented vegetable represents a small victory against uncertainty and a step toward genuine self-sufficiency.

As climate patterns become less predictable and food systems face increasing pressures, the households equipped with preservation knowledge and equipment will find themselves better positioned to maintain food security and nutrition regardless of external circumstances. The skills you develop preserving this year’s harvest will serve your family for decades to come, creating a legacy of food knowledge and independence that extends far beyond simple cost savings.

Your preserved foods represent more than mere calories; they embody your connection to the land, seasons, and natural processes that sustain human life. Every opened jar of home-canned tomatoes in the depths of winter carries the warmth and abundance of summer harvest, reminding you that true security comes not from supermarket shelves but from your own knowledge, preparation, and relationship with the earth that provides our sustenance.

Ready to expand your self-sufficiency journey? Explore our guides on building water security systems, improving soil for better harvests, and creating productive landscapes that support year-round food production.